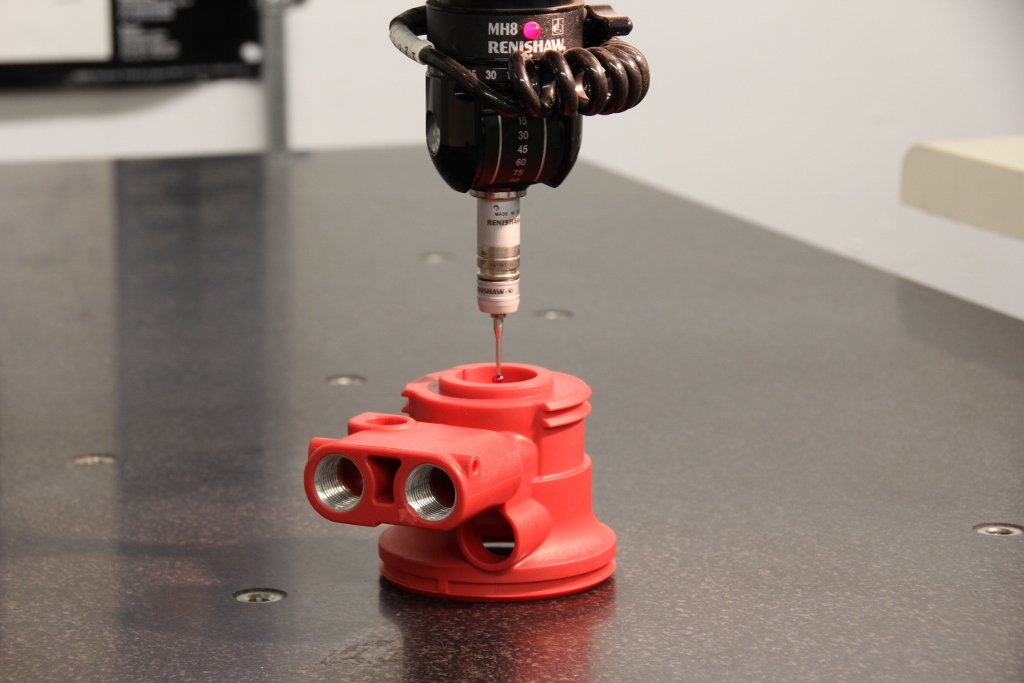

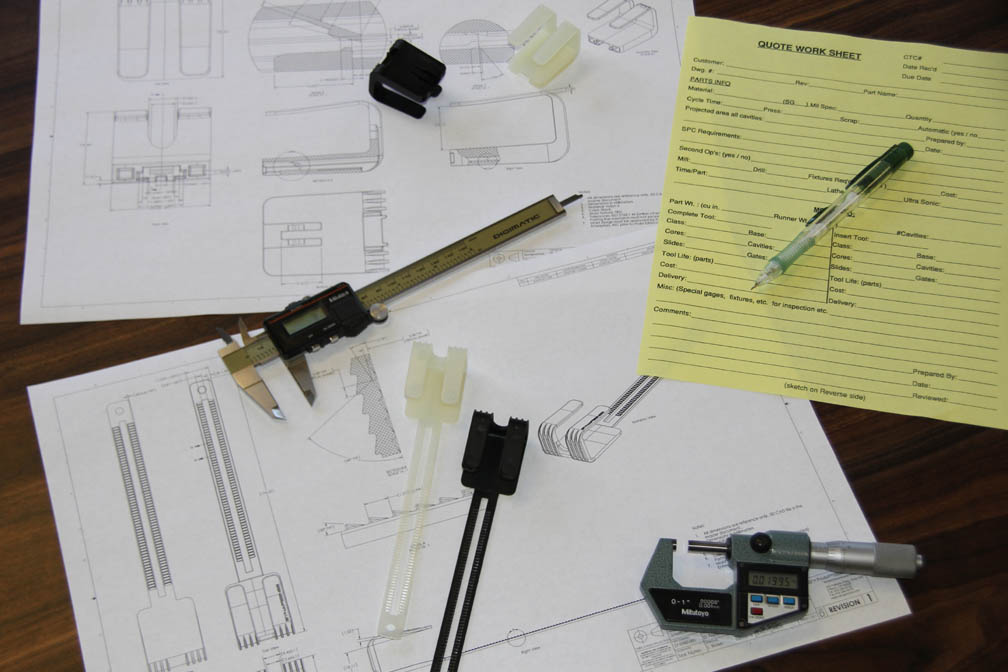

Quality is the Mission

Detailed inspection and rigid quality control procedures assure compliance with both our customer’s specifications and our ISO 9001:2015 certification. Every process is monitored, documented and analyzed by our Quality Assurance Department. They are actively involved throughout the process, from the initial stages of mold design to the production, packaging and shipment of the order. This enables us to maintain our commitment to excellence in manufacturing.

Precision Injection Molding

Operating 13 high-quality injection molding presses, ranging in size from 24 ton (1.25 ounce shot) to the 330 tons (32 ounce shot). CTC has knowledge and expertise to manufacture small to mid-sized plastic components with varying degrees of complexity and materials.

We do insert molding and over molding for complex components and assemblies.

Secondary Operations

Wide variety of assembly and finishing options available.

- Complete Assembly

- Ultrasonic Welding

- Pad Printing

- Bar-Coding

- Custom Painting and Coatings

- Hand Finishing

- Grit and Bead Blasting

- Complete Packaging Services

- CNC and additional Machining

- Insert Installation

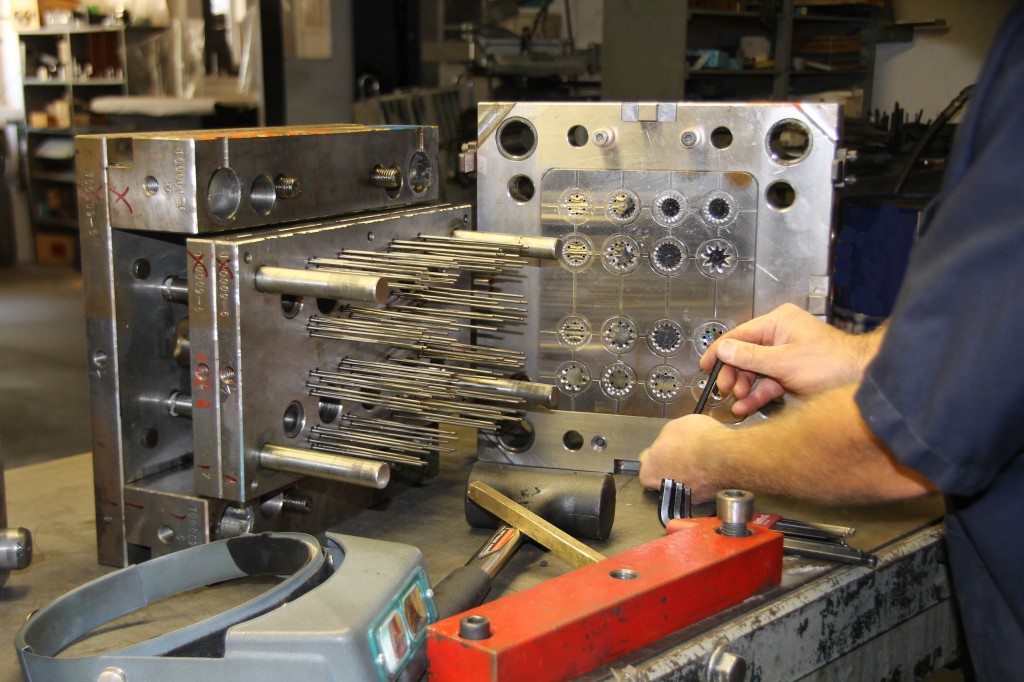

Complete Mold Manufacture

Cal-Tron Corporation offers both domestic and international mold making services.

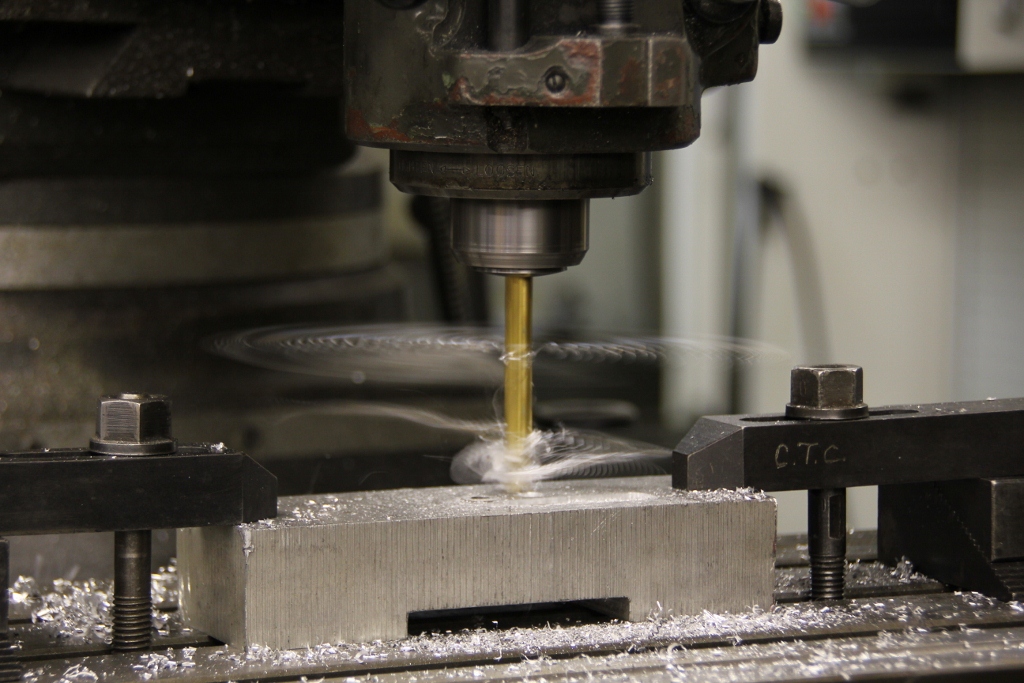

Full-service Machine Shop

CTC’s on-site, full service machine shop offers cost effective solutions by limiting down time, thus permitting quick modifications and repairs to your tooling.

Engineering & Design Assistance

Free design assistance evaluation. Our friendly, qualified staff will review your project requirements. Analyzing initial design and functionality, with an emphasis on cost effectiveness.

Warehousing/Stocking Program

Flexible stocking and Kanban programs available.